- Healthcare

- Food

Food Desiccants

WiseFresh™

WiseOxy®

MoisCon

- Applications

- About

- ESG

- News

In the majority of product packaging processes, the presence of a significant amount of moisture within the product packaging is influenced by both the packaging environment humidity and the inherent moisture content of the packaged product itself. Even after the packaging process, the interior of the packaging can accumulate moisture due to external temperature fluctuations. For products sensitive to moisture, such as freeze-dried powders, powdered supplements, granular or compressed pharmaceuticals, diagnostic reagents, and test papers, the occurrence of such moisture can lead to not only visual changes in the product (e.g., clumping, surface crystallization, color alteration) but also alterations in product characteristics resulting from interactions with water molecules present in the moisture.

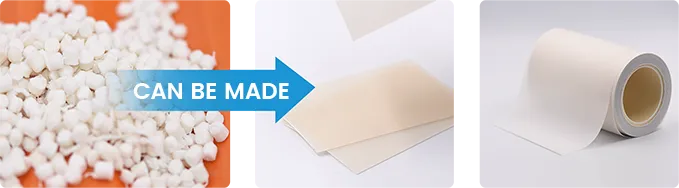

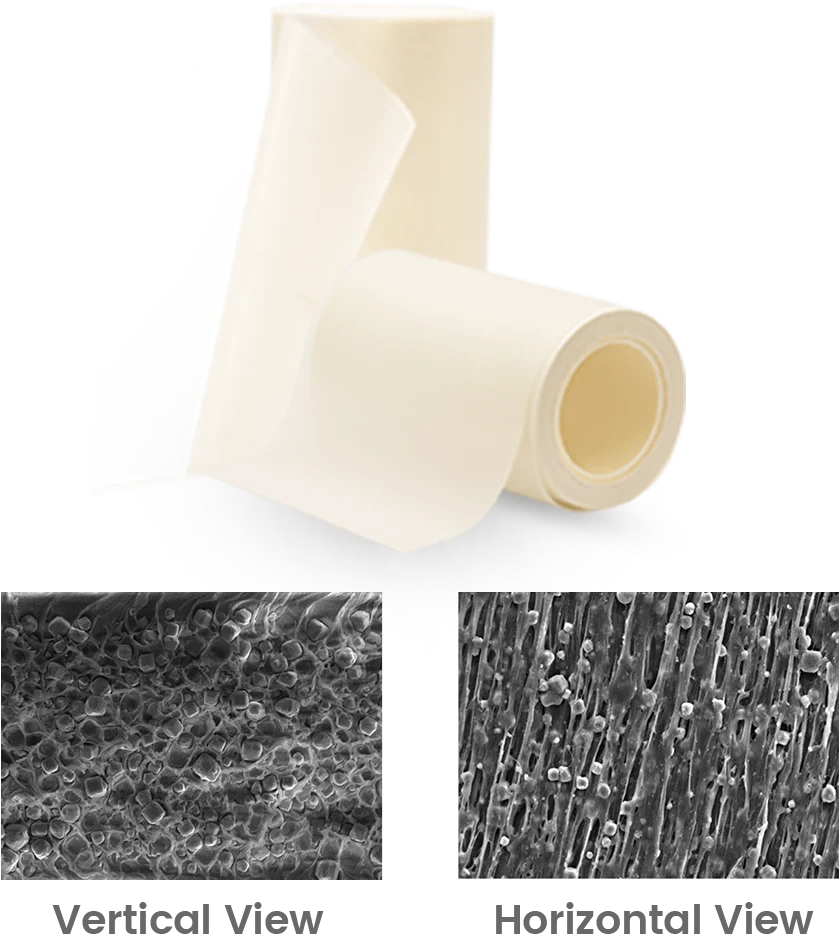

Molecular Sieve Desiccant Particle

Calcium Oxide Desiccant Particle

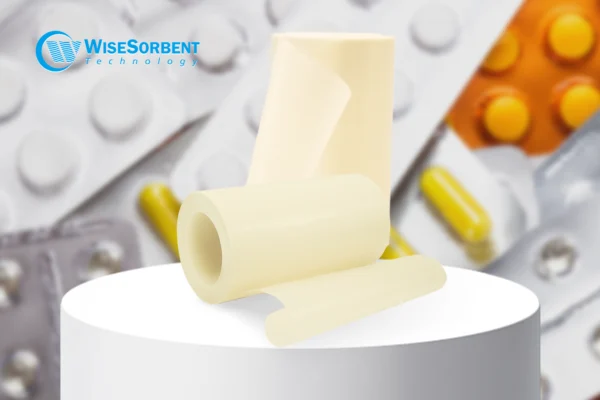

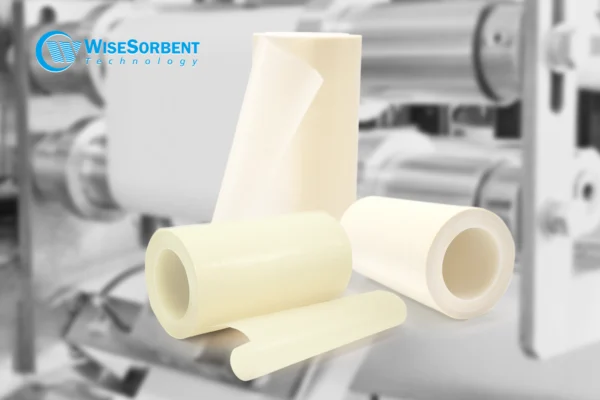

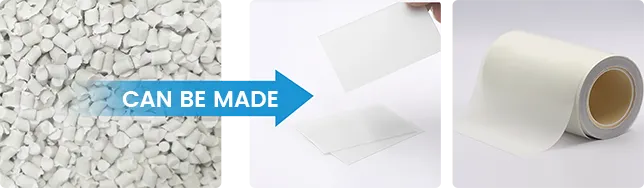

WiseFlex Desiccant Film is a functional film with moisture-absorbing capabilities, produced through the blown film process using moisture-absorbing polymer particles. The film has uniform and dense moisture-absorbing pores that can evenly absorb water molecules. When this desiccant film is laminated with other films such as aluminum, PET, or PE, it can effectively reduce the moisture content in the packaging environment, inhibit oxygen reactions, and ensure continuous dryness inside the packaging, thus protecting the stability of the packaged products.

Calcium oxide desiccant film is a common raw material in the desiccant film market. Unlike molecular sieve desiccant film, which operates via physical adsorption, calcium oxide desiccant film uses chemical adsorption. Its moisture absorption is highly effective, capable of quickly capturing and retaining moisture, making it particularly suitable for packaging applications that require high moisture absorption. Furthermore, calcium oxide desiccant film exhibits excellent compatibility when laminated with other types of films.

The moisture absorption capacity of the desiccant layer is influenced by thickness and composition variations. Under identical environmental conditions (25°C, 40% RH):

| Thickness | Moisture Absorption Capacity |

|---|---|

| 60 μm | ≥ 4.0g /m²\0.12oz/yd² |

| 80 μm | ≥ 6.0g /m²\0.18oz/yd² |

| 110 μm | ≥ 8.0g /m²\0.24oz/yd² |

| Thickness | Moisture Absorption Capacity |

|---|---|

| 60 μm | ≥ 4.5g /m²\0.13oz/yd² |

| 80 μm | ≥ 6.5g /m²\0.19oz/yd² |

| 110 μm | ≥ 8.5g /m²\0.25oz/yd² |

Molecular sieve desiccant film gradually changes from opaque white to semi-transparent white upon moisture absorption

Calcium oxide desiccant film does not undergo any noticeable color change after absorbing moisture

The primary component of the desiccant film is PE, making it suitable for various film composites (PET, PA, PP, Alu, Fiber, etc.) and enabling the production of diverse composite films, pouches, and bags. it can be widely employed in the packaging of moisture-sensitive products requiring humidity control. Sectors including pharmaceuticals, health supplements, food, cosmetics, precision electronic instruments, and military industries, can all benefit from its use.